Urban Exploration - The Green Glass Factory

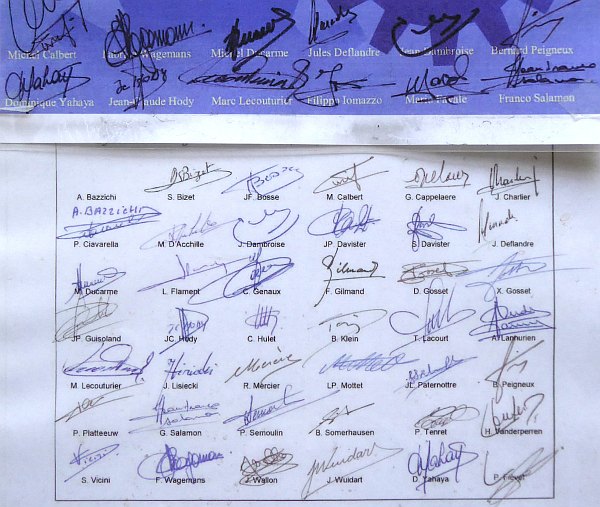

This short documentary focuses on a factory that produced flat glass intended for various specialized technical applications. I have chosen not to name the company to avoid damaging their image, especially since the industrial complex has just been sold (and rendered inaccessible by Seris PTZ camera towers). While this hampers the work of preservation and memory, the site's location—which has not yet fallen victim to mass vandalism—left little room for maneuver in this difficult choice. It is a pity, but such is the reality of many sites today. Nonetheless, those mentioned in the reconstructed personnel list will recognize themselves.

I often read in the press that this is a "glass factory." This is a term to be avoided; it is technically meaningless. It is more accurate to describe it as a flat glass production center.

Historical Background

The factory was founded in 1890. Throughout its existence, it underwent incessant mergers and process changes. Providing further detail would make the site too easy to identify. The industrial facility closed its doors in 2014 following a brutal labor dispute. At the time of closure, 190 people lost their jobs.

The factory always produced flat glass, which is distinct from hollow glass (bottles/jars), glass fibers, or cellular glass (building insulation). Flat glass is primarily produced using the float technique. We will not delve into the details of the float process here, partly because it is well-documented elsewhere, and partly because no vestiges of it remain at this site. What remains here is the beginning of the process: the silos for silica, soda ash, and dolomite.

The Production Process

The conveyors, still handsome and original, remain sturdy. Up to this point, materials were treated without mixing, kept separate in the silos. What followed was dosing, mixing, weighing, and dust removal. The precisely measured material is called the batch (mélange vitrifiable). To this, cullet (recycled broken glass) is added. In terms of raw materials, the factory also handled the crushing and recycling of flat glass from the construction industry. Note: flat glass only—no bottles! This technical approach allows for a lower melting point for the mixture.

The batch descends into dosing silos via a bucket elevator (noria). Below these remain the two furnaces. In a float line, the glass is melted in regenerative furnaces with cross-fired burners, heating the material to 1550°C.

All subsequent stages—the float bath, the annealing lehr, squaring, and stacking—have been entirely dismantled. The crate-making shop is empty, as is the sample workshop. The factory possessed its own power station (a beautiful, old-fashioned structure, though heavily victimized by vandalism and theft), its own water tower, laboratory, infirmary, and administrative block.

Economic Decline

For a long time, the plant produced mirrors, laminated glass, fire-resistant glass, safety glass, and acoustic glass. Later, influenced by a general economic slowdown and a temporary market bubble, the site produced flat glass for photovoltaic panels. Due to fierce dumping (thanks to Europe, as usual), a path was cleared for Chinese products manufactured under deplorable conditions. This unfair competition plunged the establishment into a cycle of significant losses, ultimately leading to the site's downfall.

Wandering Through the Vestiges of a Bygone Era

When one thinks of the persistence of the workers to constantly improve the process—the effort and the lack of recognition—only to be left behind by shareholders growing fat on profits, it is a story all too common today.

Entering the factory is a cold shower. There is a marked sense of unease; a neighbor has even barricaded "their" land with massive "Private Property" signs. Beyond that, the atmosphere is grim. The "welcome" consists of two mobile towers equipped with PTZ cameras capable of motion analysis (distinguishing between a deer, a pheasant, or a human) and transmitting alerts to site security. All of this to guard an expanse of empty halls—but people stop at nothing these days, including arson. In short: empty halls under alarm.

The word "halls" is certainly appropriate here. The site is a gargantuan collection of shed-roofed halls, built empirically side-by-side in haste, without architectural cohesion. No two are alike; everything was tacked on according to the needs of the moment. Consequently, in the complete absence of landmarks (the place is absolutely, utterly empty), orientation is difficult. Even in the oldest halls—abandoned for ages—it is clean to the point of having been scrubbed. Add to this the fact that demolition and decontamination have taken place; essentially, the site has been scraped clean.

The only curiosity—and the reason for this site's fame—resides in the two furnaces. Through an act of vandalism (or perhaps vengeance?), the last batch was never emptied. The glass solidified on the hearth, easily reaching a thickness of 1.20 meters. This renders the furnaces totally unusable without massive renovation. The contents form a layer of green glass that has crumbled into large, shapeless blocks against the doors, which have been completely torn away. The industrial landscape is undeniably aesthetic; the glass creates a striking tableau. Technically, however, it is a disaster.

What remains to be seen stands before and above us. A mixing tower still holds a curious large conveyor enclosed in a pipe, as the batch was a powder of very fine grain. High up are the dosers, which fed the required quantities into a particularly aesthetic bucket elevator. The silo still exists, along with a few purge pots, standing like stage props in the middle of very dusty staircases.

Ultimately, this empty immensity takes on a certain charm; it is a city within a city. Crossing the entire factory via high-perched gratings on the rooftops gives a strange impression. The structure of this industrial complex almost erases the outside world, even now while unoccupied. At the center, there is nothing but an endless deluge of diverse rooftops. These great spaces have been colonized by birds, who find sanctuary in these deserted shelters.

Let us now explore these industrial halls.

.