Urban exploration - The coal washing plant in Carmaux

We received photos from a traveler and compiled them into a historical summary.

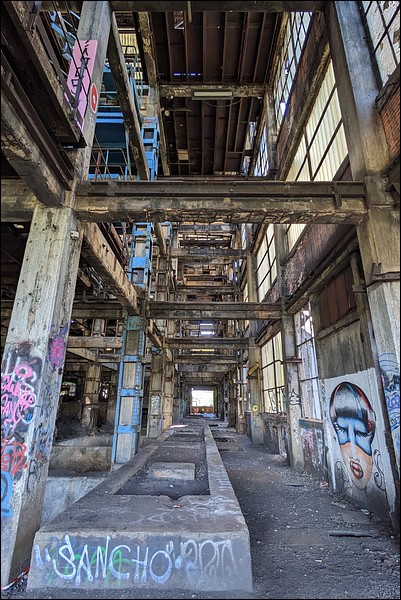

Here is a visit to a coal washery (lavoir à charbon); very few of these remain as almost all have been razed to the ground. This one is immensely disappointing in terms of its content for two reasons: firstly, the machinery has been entirely dismantled, and secondly (once again), absolutely frenzied vandalism has taken place. All that remains is a vast, tagged, and fouled carcass. Nevertheless, from the outside, this former washery still appears monumental and striking.

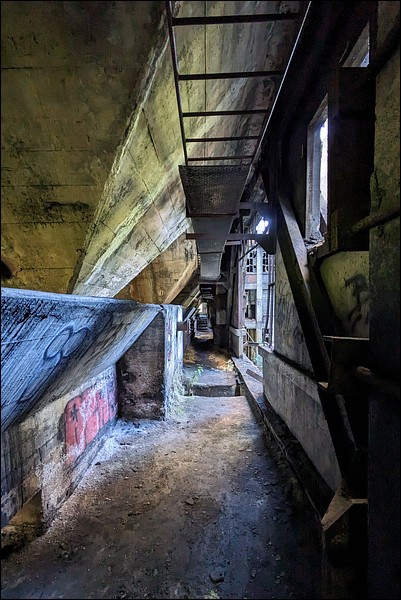

The structure must be considered eminently dangerous. There are holes everywhere. That is not so much the problem, as they are visible. More importantly, the steel plating is extremely worn out. It could give way at any moment under the weight of a person. The thin layer of coal dust hides these structural failures. Added to this is the relatively deplorable state of the concrete in certain sections, particularly near the water towers. In this moribund context, the site is heavily frequented by all sorts of people. Consequently, an accident is no longer a matter of "if," but "when." It will provide more "grist for the mill" for the press, who will have a field day with it—a true misery.

The principle of coal washing is far from a simple affair. Upon leaving the mine, the "run-of-mine" (tout venant) is loaded with shale, gravel, and dirt. In ancient times, it was women—known as cafus—who did the sorting; however, mechanization quickly replaced this grueling labor.

First, the raw material is placed in immense silos: here, they have been reduced to large piles of rubble but are still visible on the ground. A specific feature of this basin is that the material was brought up via two immense inclined planes (nearly 800 meters long), which is practically unique. These were called fendues (slits/drifts). Thus, there was no shaft, but rather a conveyor system.

Next, sizing (calibrage) is performed to separate the large lumps from the coal fines (poussiers). The large pieces are passed under water jets, which serve both to wash away the dust and to remove soil. After this sizing, the material passes into the Drewboy, a piece of equipment that is more than just central—it is the heart of the operation.

Imagine a giant Camembert box, tilted at a 45-degree angle, with compartments inside. This "box" rotates slowly. It is half-submerged. A conveyor belt brings the raw material inside. The coal floats, while the rocks sink. Consequently, the rocks are simply evacuated and will later form what we know as a terril (spoil tip) or crassier (slag heap), depending on the region. The coal is kept.

The liquid used is not just water. It is a heavy medium (liqueur dense). It is a mixture of water and magnetite—which explains the considerable boom of magnetite mines like those in Cogne, for instance. This also explains the presence of the two large water towers.

As for the fines, they are placed in jigs (bacs à pulsations). These are long tanks in which wave-like motions are created, similar to the sea. The coal rises while the rocks remain at the bottom. In neither case was de-ashing (décendrage) performed.

Once the product is washed, it is placed in silos—still clearly visible here—which allow for shipment by train.

This washery was commissioned in 1928 and opened its doors in 1932. It naturally evolved over the decades, notably in the 1950s. Directly connected to Blaye-Les-Mines, it processed about 500,000 tons per year with a workforce of 3,500 miners; the washery itself employed fewer than 200 people. Rather than focusing on precision and refinement, the operation here was about brute force and mass production. There is no fixed date for its closure, but it was sold in 1997 and never returned to service.

Honestly, I don't know how this monolith can endure without more accidents occurring. It’s going to give urbex yet another "stellar" reputation.